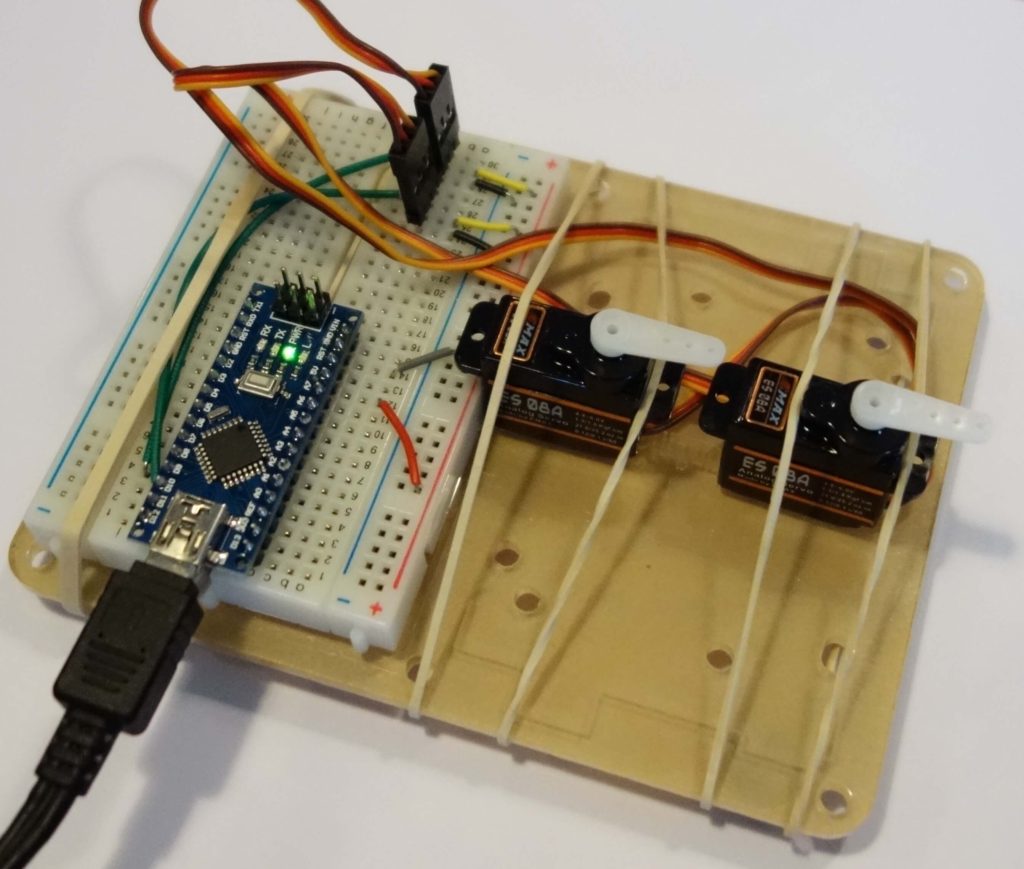

Over the past few weeks I have been working on building the software to allow my RC Sailboat to sail autonomously. To keep the form factor as small and light as possible, I bought a cheap Arduino Nano clone to use in place of an Arduino Uno.

Obstacle 1: drivers

My first obstacle was getting my mac to communicate with the board. The basic issue is that the WCH340G USB interface chip on the clone is different than the FTDI FT232RL used on the authentic Arduino Nano. There are many sites with instructions and links to drivers, but this one had the most up to date driver that was signed. The older drivers were not signed and required me to bypass OSX’s security to allow unsigned drivers. direct link to driver download

Obstacle 2: consistent power

I had some semi-working software running on the Uno that would adjust a sail and rudder servo. When I swapped in the Nano the servos generally worked, but would sometimes move wildly or jitter. Since the Nano and Uno are very similar (chip, ram, clock speed, etc.) I figured the issue was going to be with the power or maybe the WCH340G USB chip.

To troubleshoot, I used my voltmeter to see how the Nano voltage changed while adjusting the servos. When not moving the servos, it put out 4.8V on the 5V pin and while moving the servos simultaneously it would drop to ~4.2V. The servos expect 4.8-6V so this could contribute to the issue. As reference, the Uno put out 5V, I didn’t test it while moving servos.

In the past I have had issues with macs not putting out enough voltage through USB, and I have a cord that includes 2 plugs, one for power and one for power+data. The cord is similar to this one.

I swapped out the cords and the servos started behaving as expected. My guess is that a combination of data transfers (to signal the servo change) and keeping a consistent power supply were too much for the single cord.

Since I want to run the system without my computer, I think the USB cord is not the best solution. A couple of alternative options are a separate power supply for the servos, or using a capacitor to smooth out the power.

To keep down weight and complexity, I took the capacitor approach. I found many sources that said a minimum of 470uF was the correct capacity and that the voltage rating should be 3x what you have in the system. I added a single 1000uF/25V capacitor with the old cord and the servos behaved well. The servos also worked well with three 100uF/16V capacitors in parallel, but I prefer the single capacitor solution.